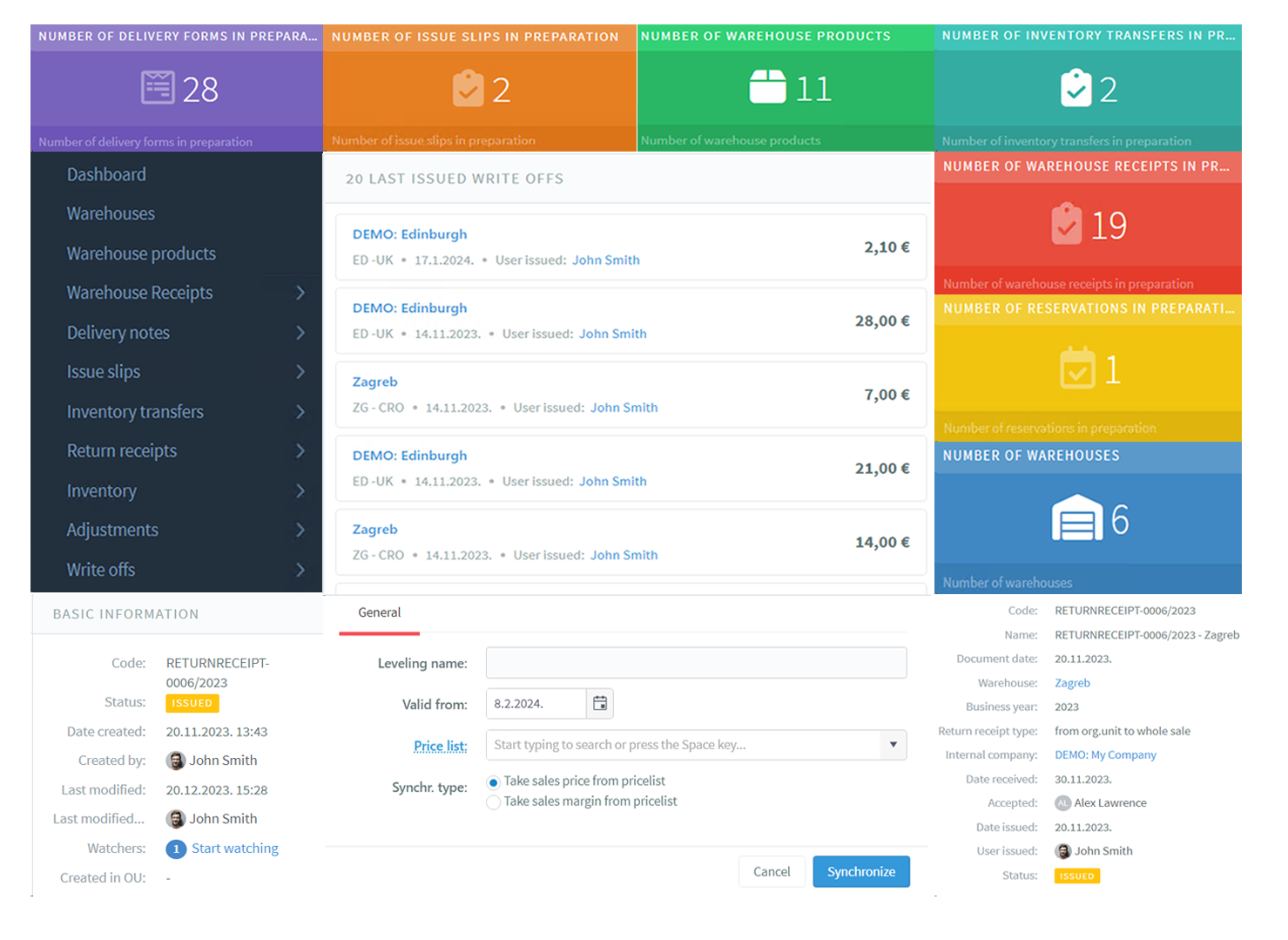

Storage

The storage module allows employees to record detailed work with warehouse items from their receipt, intermediate, shipment, issue and finally write-off. It is possible to review each warehouse document and see how it is related to the trajectory of the warehouse item and access in one place all the data from quantity, financial values, movement of the item and other records.

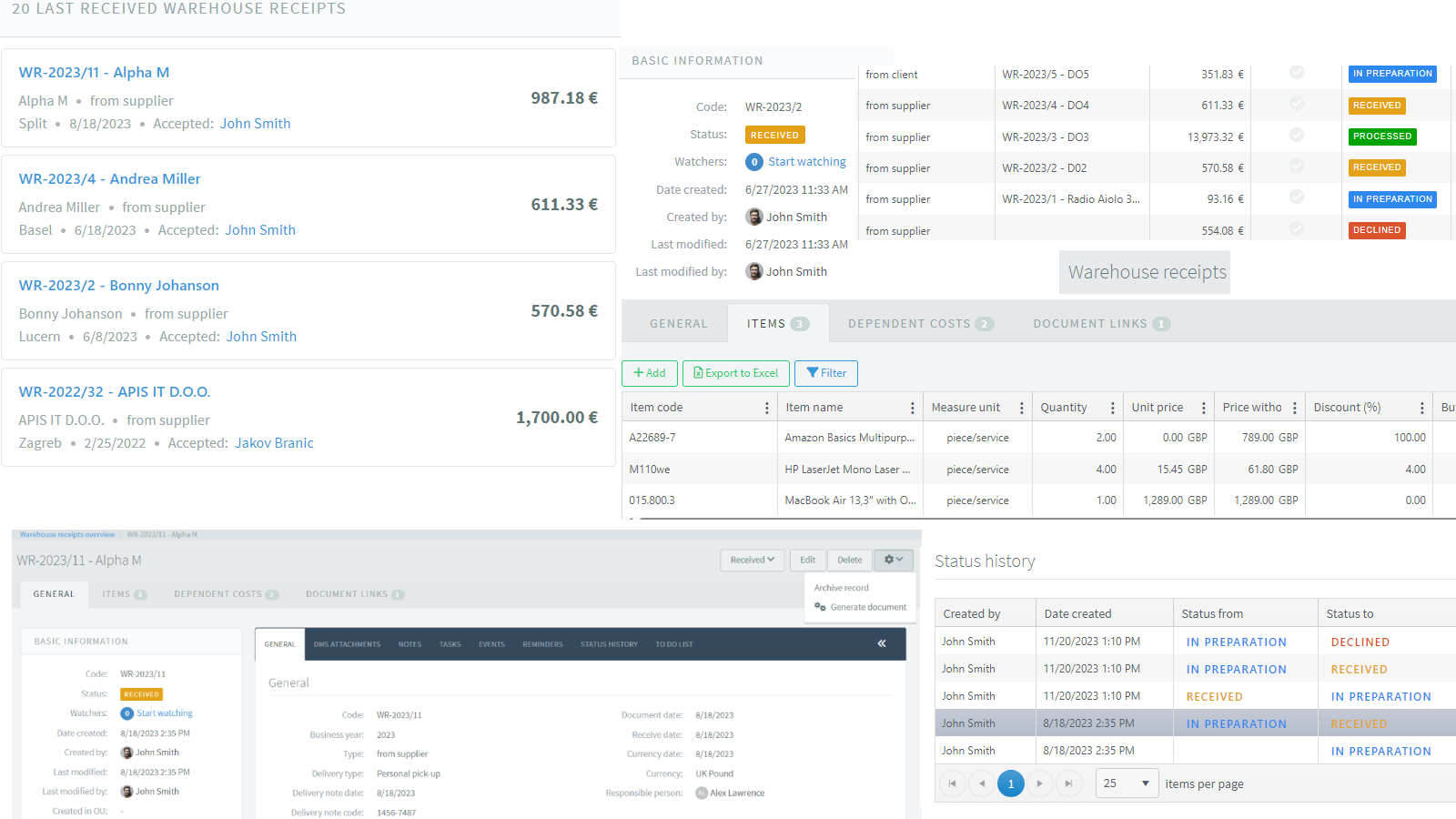

Warehouse receipts

Receipts include detailed records of receipt of warehouse items in the warehouse. In addition to a detailed overview of all items and their financial values, users can update and add incurred costs related to the receipt. After receiving the receipt, the received quantity is automatically recorded in the warehouse and the user is reduced in the time he would otherwise spend on additional documentation and subsequent changes, as well as checks on the quantities and condition of warehouse items.

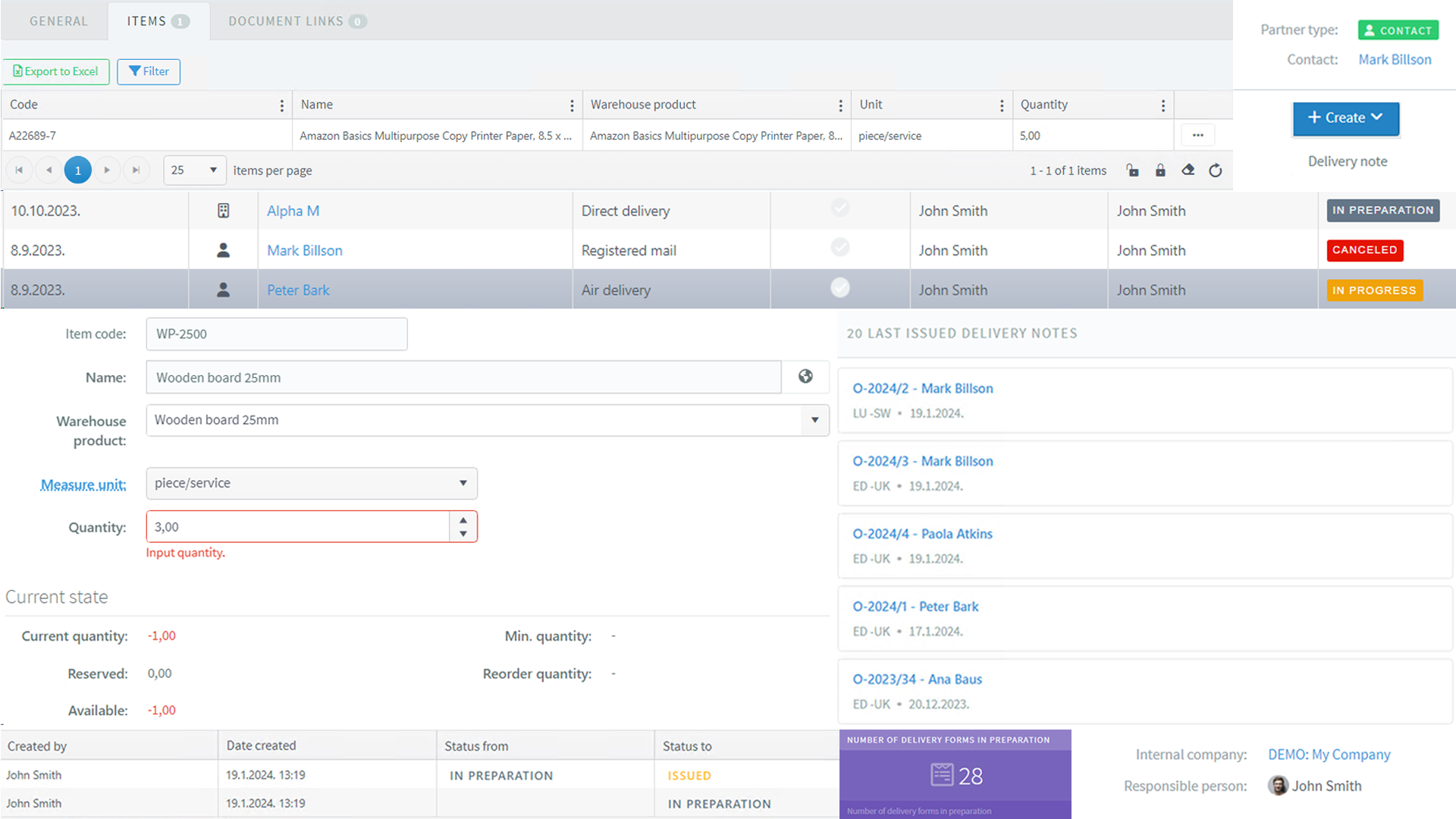

Delivery notes

Delivery notes are a warehouse document for shipping warehouse items from the warehouse to a partner (company or person). After the delivery note is issued, it is stored in the warehouse, and the quantities of the items on the delivery note are taken from the warehouse. The delivery note is a basic document in the warehouse business, which is used to ship goods to parterres. The delivery note is the basis for creating an outgoing invoice.

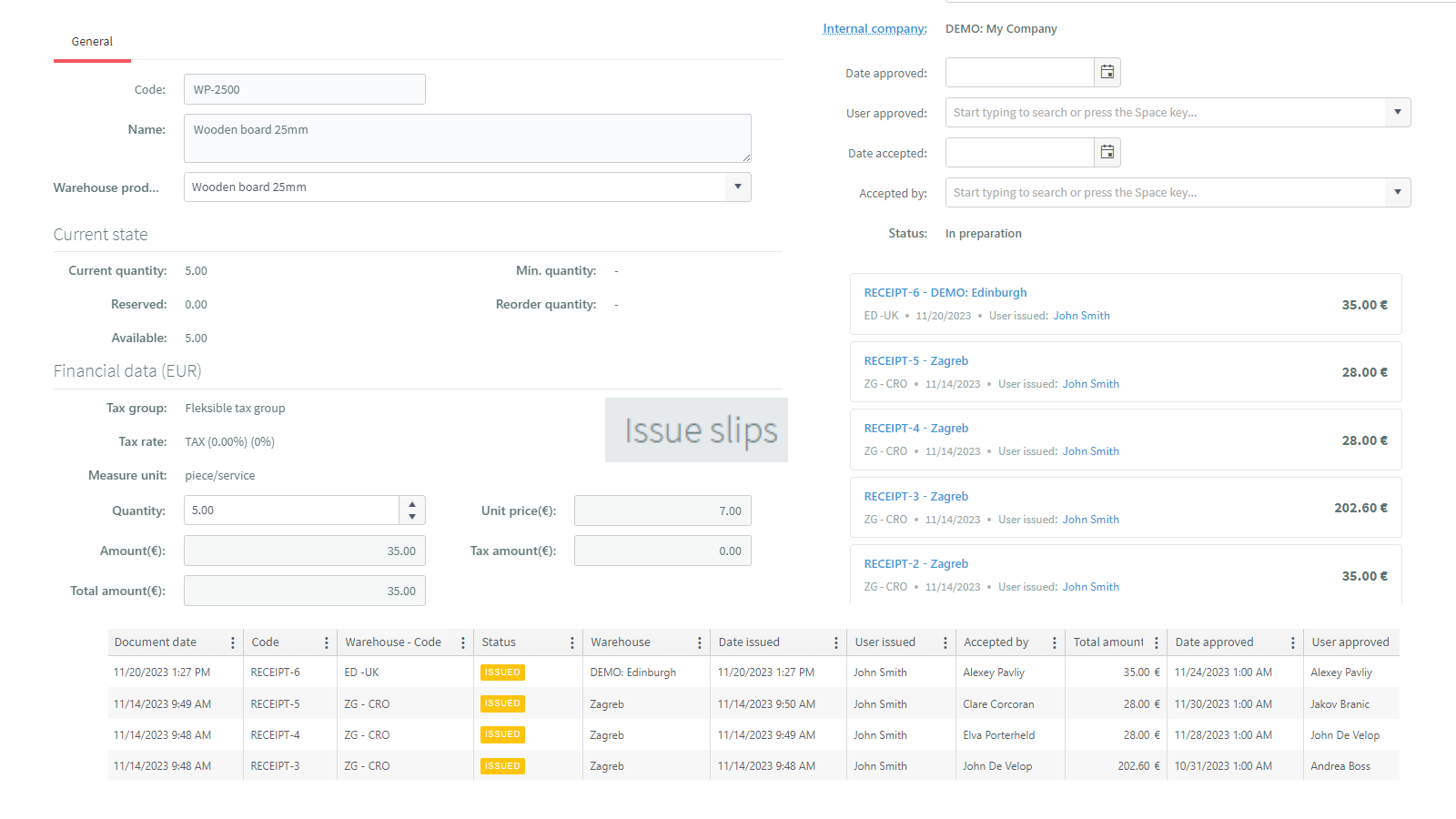

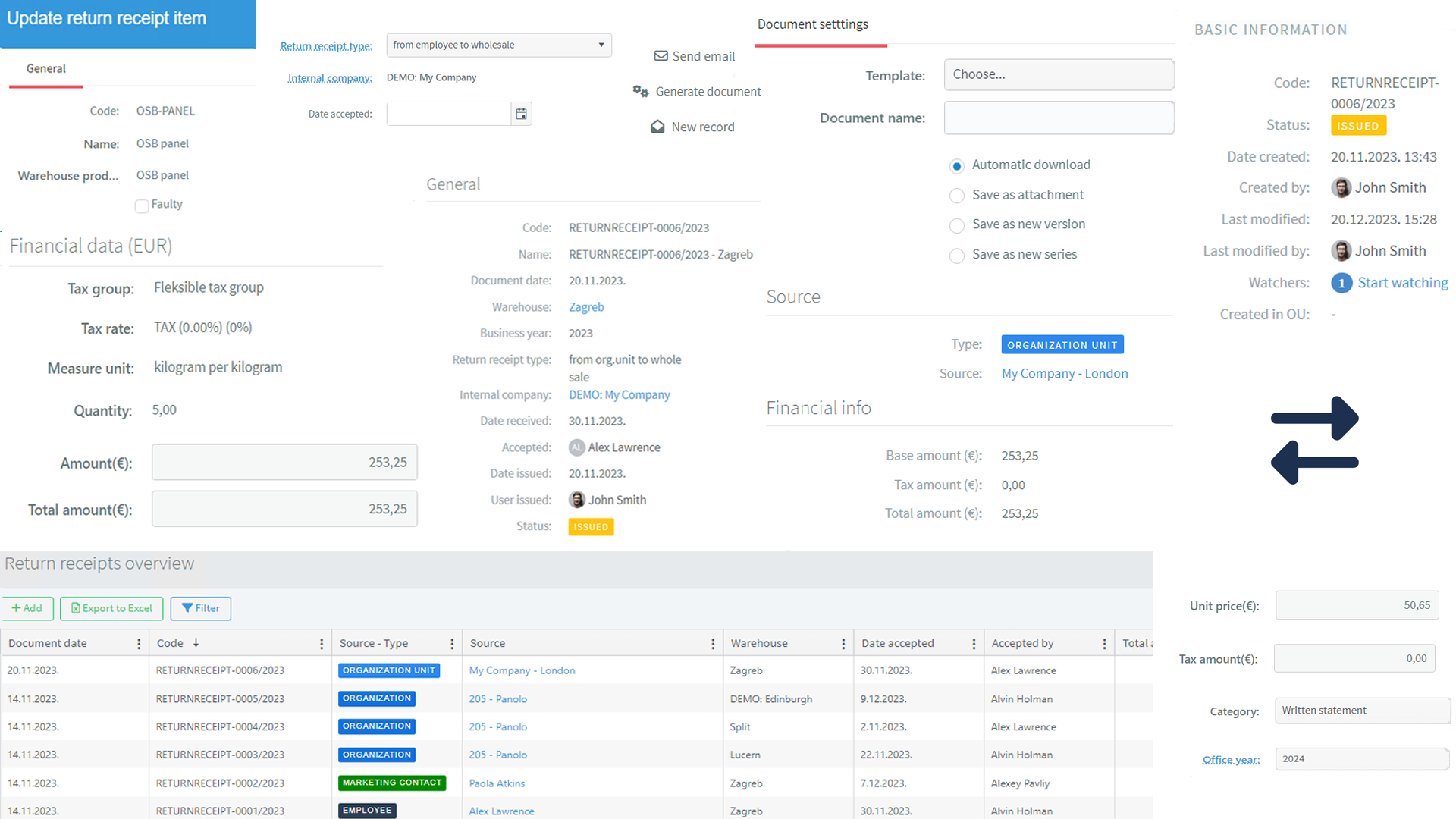

Issue slips

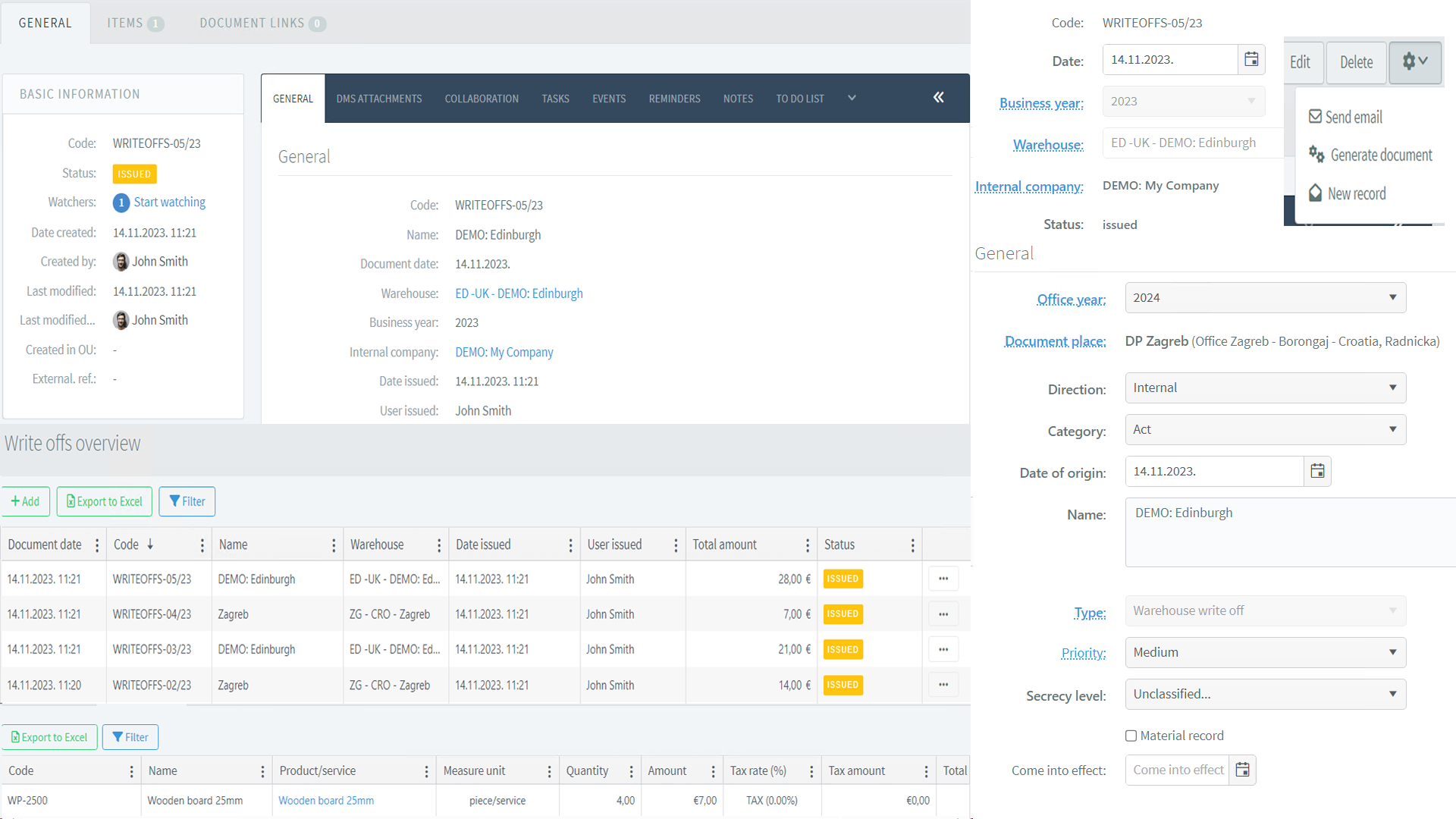

Issued documents are warehouse documents that are used for issuing warehouse items outwards, i.e. items are “deleveraged” in terms of consumables or exclusion from storage for specific purposes. Issue slips are issued and after its issuance, the registered quantity of the warehouse item in a particular warehouse is automatically reduced. In this way, the flow of movement of the warehouse item continues from its receipt through the return receipt to the release from the warehouse.

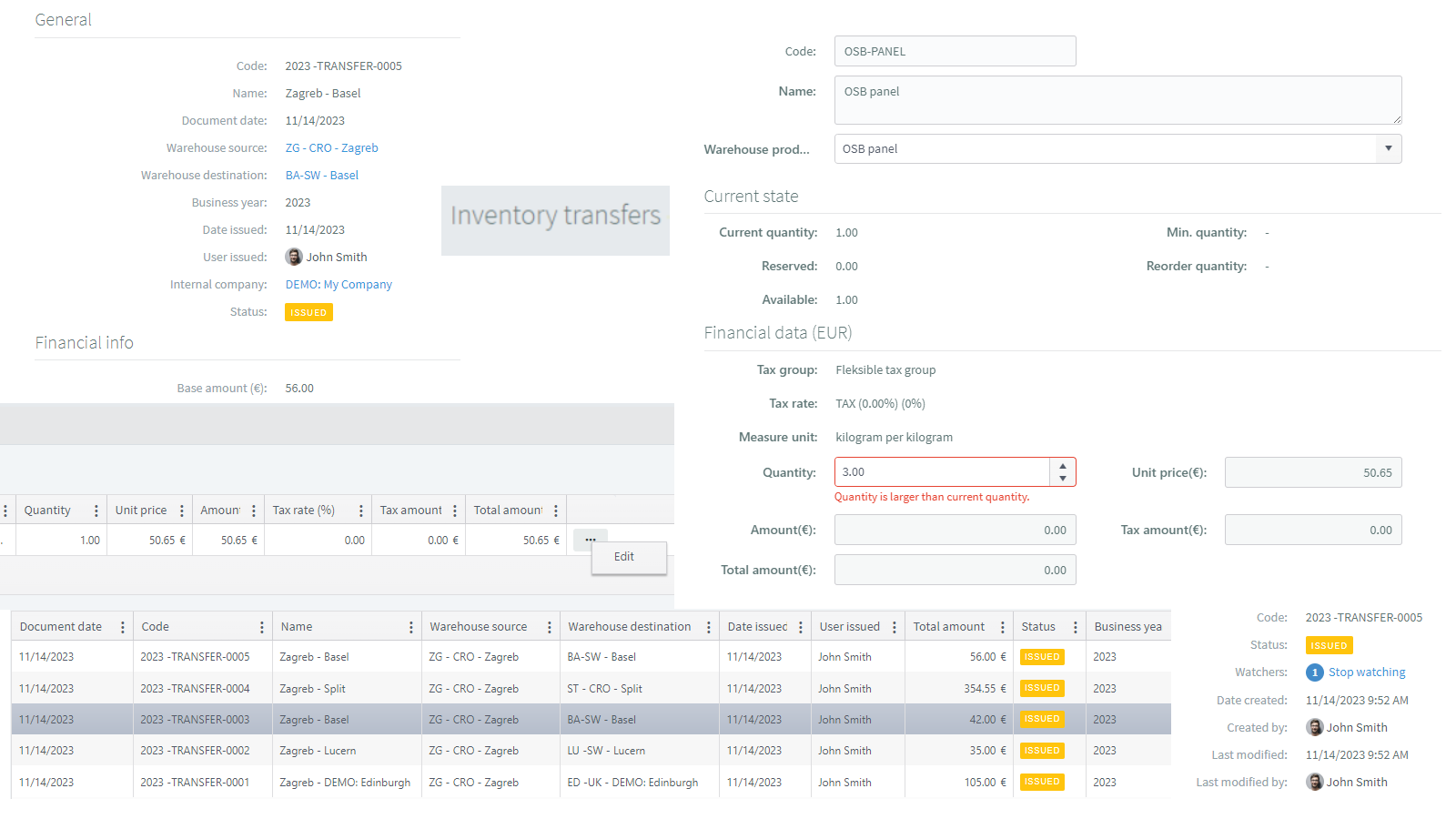

Inventory transfers

Tracking of intermediate stocks of warehouse items is enabled through a warehouse document called intermediate warehouses. They are an internal document intended for moving or sending warehouse items from one internal warehouse to another. After the intermediate warehouse is sent and accepted, the initial quantity on the initial warehouse is automatically reduced and the initial warehouse is increased at the destination warehouse.

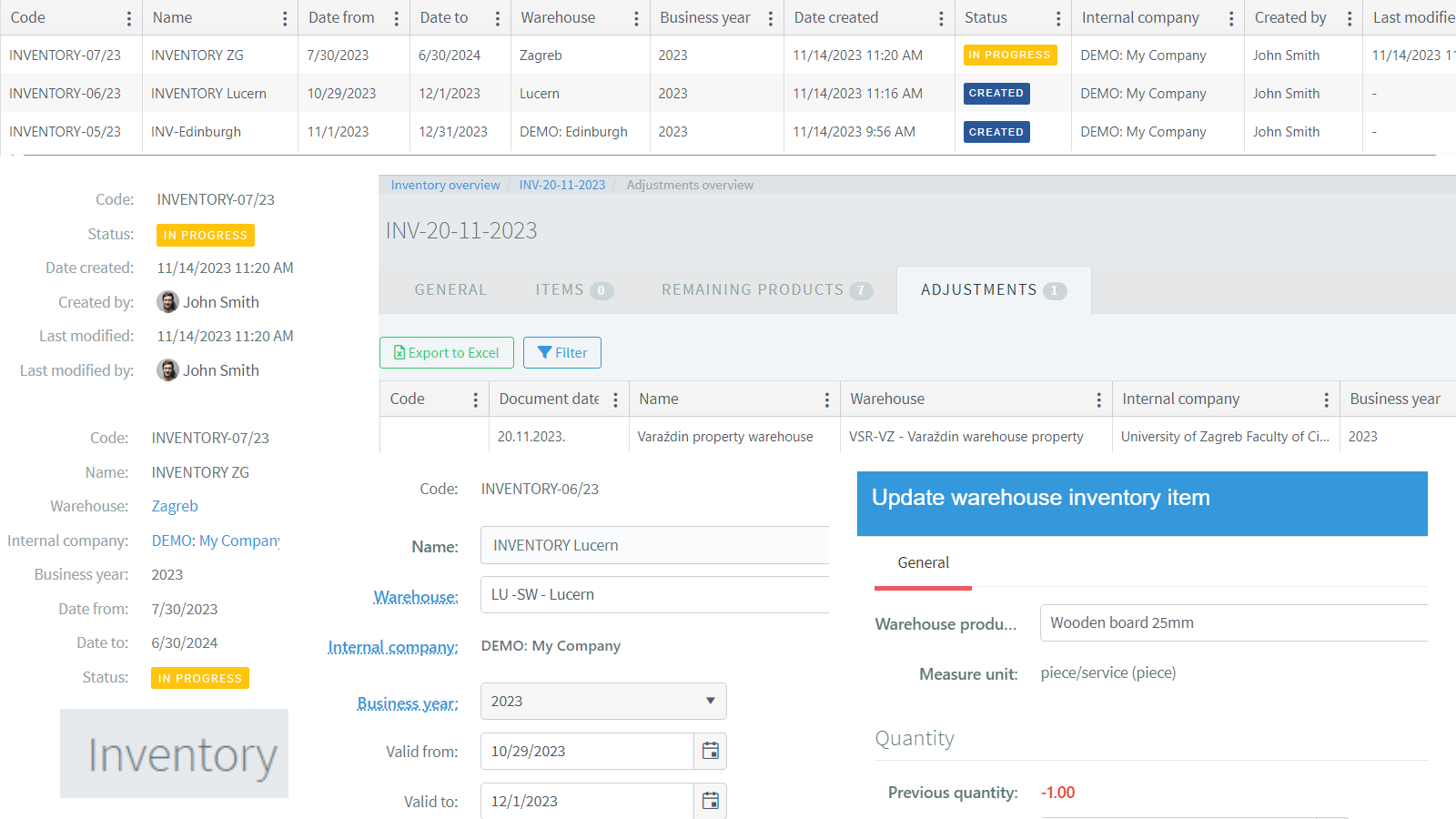

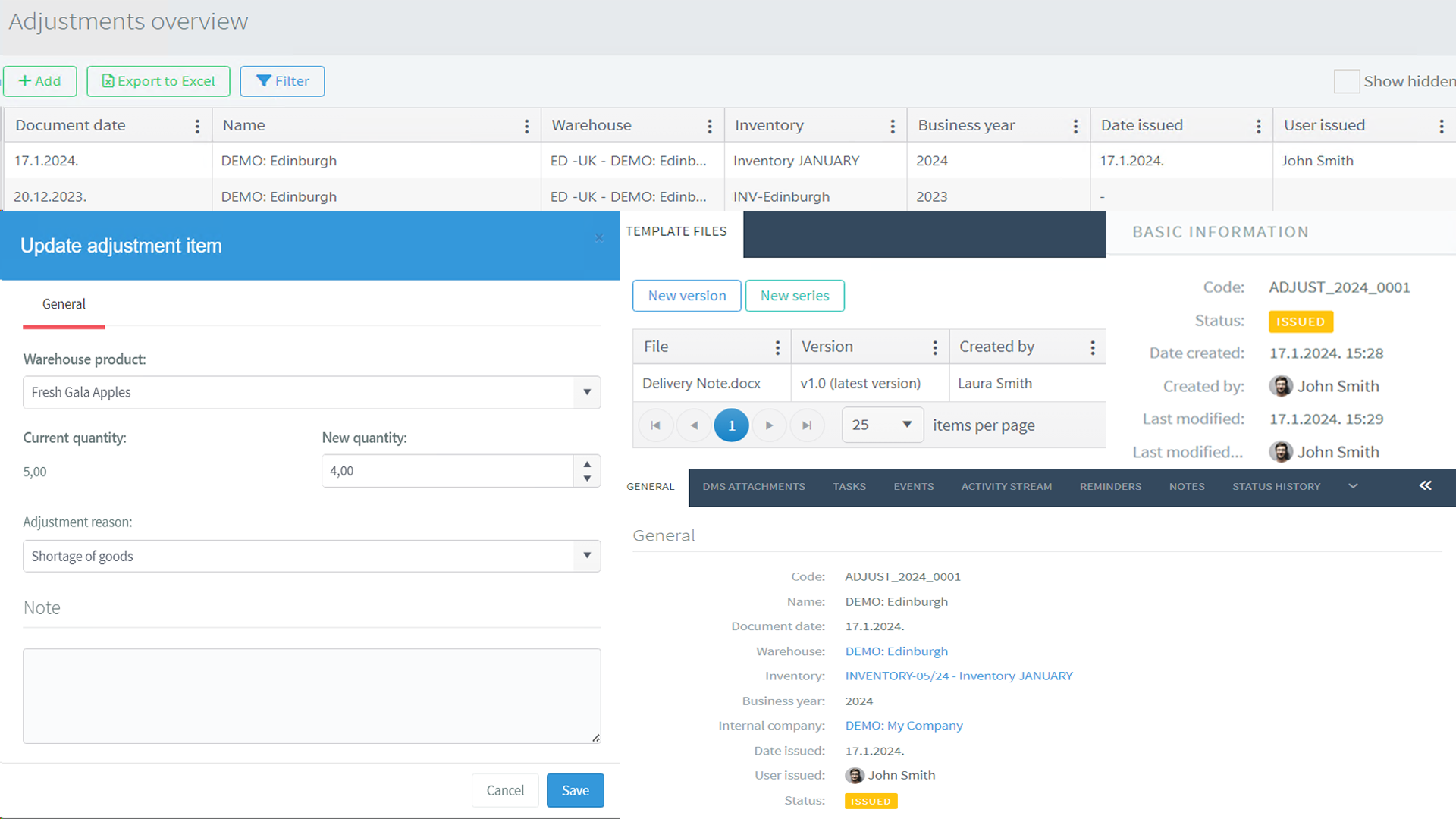

Inventory

Warehouse inventories represent a record and documentation of the current stock level in the warehouse. They include a detailed overview of all manipulations and sending items to and from the specified warehouse. Warehouse inventory can also be processed with various corrections in quantity, which is recorded in the system through the so-called storage. Put-aways are a separate warehouse document that is intended only as an addition to inventory.

A flyer with more information about this subsystem and its modules:

Download

Hrvatski

Hrvatski Français

Français Deutsch

Deutsch